The following is a post by my friend Jason, who is not a regular contributor, but has posted in the past on our 3D magazine printing project. I thought this would be an interesting addition, and a demonstration of how technology is making gun control a virtual impossibility. Below is his post.

-Sebastian

I’ve been meaning to try this for a while now (using the AR-15 lower receiver solid model from http://www.cncguns.com/downloads.html), but I wanted to do it using all open source software, and was having trouble finding something that could generate tool paths from the AR-15 model. PyCAM seemed to be the best bet, but whenever I tried it on very complex model it would very quickly use up all the memory (8GB of ram plus 8GB of swap) and bring the computer to a screeching halt.

I recently had a project at work where I needed to make a much simpler part, and not wanting to go back to using BobCAD under Windows, I gave HeeksCAD and PyCAM a try. It worked out pretty well, and in the process I discovered and fixed a memory leak in PyCAM

PyCAM is still horribly inefficient in its memory usage, but with the memory leak fixed and a new computer with 16GB of ram I was finally able to generate decent toolpaths for the AR-15 lower.

The equipment/software:

- A small Taig desktop CNC mill. http://www.microproto.com/MMDSLS.htm

- EMC2 for controlling the mill. http://linuxcnc.org/

- HeeksCAD for model manipulation. https://github.com/Heeks

- PyCAM for toolpath generation. http://pycam.sourceforge.net/

So now I’m all set to give this a try, but I can’t find the block of aluminum I had intended to use. But I did have a block of Delrin left over from an earlier project, and Delrin should be strong enough to handle a .22 cal upper. So I’m trying to make a delrin lower first for use with a .22 cal upper, and if that works I’ll order some aluminum and make another lower for use with a .223 upper.

Note that I’m not an expert in material properties (nor a machinist) so don’t take the above statements to mean that its safe to fire an AR-15 made of Delrin. Do at your own risk.

The original block of Delrin.

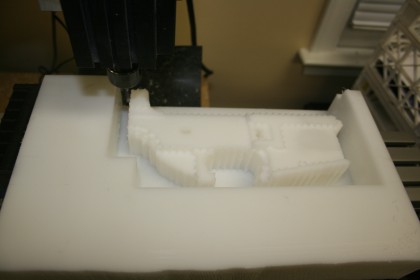

After a first pass rough cut with a 0.25″ diameter end mill.

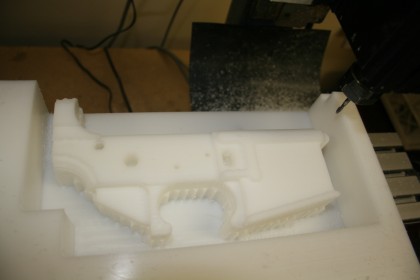

After a second pass using a 0.125″ end mill and a much smaller grid size.

After a finishing pass with a 0.125″ ball nose mill.

Now things are going to get a little complicated. I’m going to have to make some sort of jig to hold the part in place while I machine the other side.

This kind of thing puts a big grin on my face… and makes my bank account feel woefully inadequate.

So much for gun bans. Keep up the good work.

Send me an e-mail. I can set you up with a solid model of the jigs you need.

I can’t supply jigs for you, but I would suggest a jig based on the location of the action pins. That way you could predrill the pins and lock the block into the jig for both cuts. Could help with side to side alignment.

Sweet. I have a manual mill I’m learning on now. CNC would be awesome but is $$$.

Check out this guy’s site: http://cncguns.com/

He has made pistol frames and a AR-15/45acp

lol. maybe I should read where you got the cad drawing before posting.

Weaponeer has documented ar15 lowers built out of wood and hdpe cutting board.

The lower is not a high stress part. The high stress area of the lower is the bridge between the buffer tube attachment and above the selector switch. Plum crazy had some issues with their poly lowers with cracks in this area.

I would NOT, repeat NOT shout any thing out of a firearm made from Delrin. But I would use Delrin as a quick proof of concept and parts fitting if you are going to make a real firearm at some point. Its is a lot cheaper then quality Alu, or Steel, and should be able to machine it a lot quicker(say 2 or 3x tool movement(not RPM) speed). and i am all for testing out tool pathing and what not on cheap stuff before running a good block of quality metal. and it would make a perfect platform for testing jig setup and what not. :P

The AR-15 lower is not all that high stress a part. The boom is contained by the upper. I think if you did a .22LR upper, it would take the recoil just fine. I’m not sure I’d shoot .223 out of a Delrin lower, but I’d actually bet it would work ok, at least for a while. The only stress the lower really gets is holding the magazine in, and holding the stock in place while the rifle recoils.

The M&P 15-22 not only has a poly lower, but a poly upper as well.

As a wise man one said, you gotta know your limitations.

Very nice. I am curious how you intend to fabricate the buffer tube hole (and the spring detent pin holes) as I was never able to figure out a suitable way to do it on a taig (Z too small)

if you want to try remaking it, face the stock flat if not already flat enough, leave some beefy tabs on surfaces that are easy to clean up later, and you will only have to make vice jaws to hold it when both sides are machined

I’m hoping that if I slide the headstock up on its mount as high as it will go without coming loose I’ll have just enough clearance.

If that doesn’t work I’ll try mounting the headstock horizontally so that I can use the X axis for the Z axis.

good luck, I look forwards to seeing the results. if you haven’t seen it already check out firearmfiles.com There is an AR lower designed specifically to fit within the taig envelope there in the downloads section (see the slab sided lower)

Keep in mind that in the AR15 the pressure of the fired cartridge is contained by the bolt locking into the barrel extension. The lower receiver is simply a frame to hold the fire control group, magazine, and buffer tube. Cav Arms made polymer lowers for years as did Professional Ordnance (who was later purchased by Bushmaster, who sold AR15s with polymer lowers).

It should be perfectly safe to shoot an AR15 with a plastic lower regardless of the chambering.

Nice Build.It should work fine for a lower probably should have just milled the trigger guard into the lower those ears with that type of material probably be pretty weak.

Check out the pdf book on ray-vin.com/ar15. He has the prints drawn up for jigs. I made a set for the forgings that I’m working on. Great project, good luck!

So how do you mill the other side?

Hello there!

I was wondering about this publish and find some cool things the following http://www.solidface.com.br

Hope it will help you guys

You actually make it seem really easy together with your presentation however I to find this topic to be actually something that I feel I’d never understand. It kind of feels too complicated and very wide for me. I am looking forward on your subsequent put up, I’ll try to get the hold of it!